Below are our core services and the process by which we deliver value and reliability to our clients:

Core Services

- Client Requirement Screening

To initiate the involvement, we first must review and analyze the range of product types you would like to address, specifications requirements, order quantities, design style, spending limits, markets you are attempting to penetrate, required quality, compliance needs and packaging requirements, to then build a sourcing strategy that best meets your needs.

- Supplier Sourcing & Assessment

Using our extensive network of approved manufacturers or artisans located in various regions of India, we would identify acceptable suppliers. We would assess their technical capabilities, capacity for your requirements, previous exporting experiences, design ability, materials sourcing, and demonstrate the necessary quality.

- Factory Audit

We would perform an audit covering one or more areas including but not limited to, ethical and labor practice, environmental compliance, safety, material input, machinery used in production, to quality assurance process if used. We would ensure that the supplier complies with your product specifications, as well as suffice to do business at least within a reasonable range of ethics.

- Samples or New Product Development

We can develop samples before bulk orders. You can send us your designs or prototypes for replication. If you need new designs, we can support the design, prototypes, material selection, colour matching, finishing, trims, etc. This reduces risks in the final production.

- Negotiation & Contract Management

We negotiate purchase price, terms of payment, lead time, product specifications, and then document the agreement clearly. We manage your contract with the supplier to protect your interest and clearly communicate expectations.

- Production Monitoring

We monitor production during the production cycle at key checkpoints: Receipt of raw material, production in process, mid production checks, and making sure we stay on timeline. We monitor processes to ensure production standards, workmanship, finish, tolerances all meet expectations at each stage.

- Quality Control & Inspections

Before shipping, we conduct a final inspection to check for defects, consistency, finish quality, consistency of color, safety compliance, and packaging quality. If needed, we perform 3rd party lab tests (for materials, finishes etc.) in order to meet your regulatory or certification requirements.

- Monitoring Packing & Labeling

Packaging and labeling is an important step to ensure safe transit and correct customs clearance. We monitor packing and labeling to ensure strength and appropriateness (i.e., carton, cases, padding, etc.) and that labeling is met for the buyer, legal, and country regulatory requirements to the destination.

Reasons to Choose Sri Abhishek Merchandising:

- End-to-end solution: Having to deal with multiple vendors or intermediaries just means adding layers of complexity to your supply chain. We will be your full supply chain partner from concept to delivery.

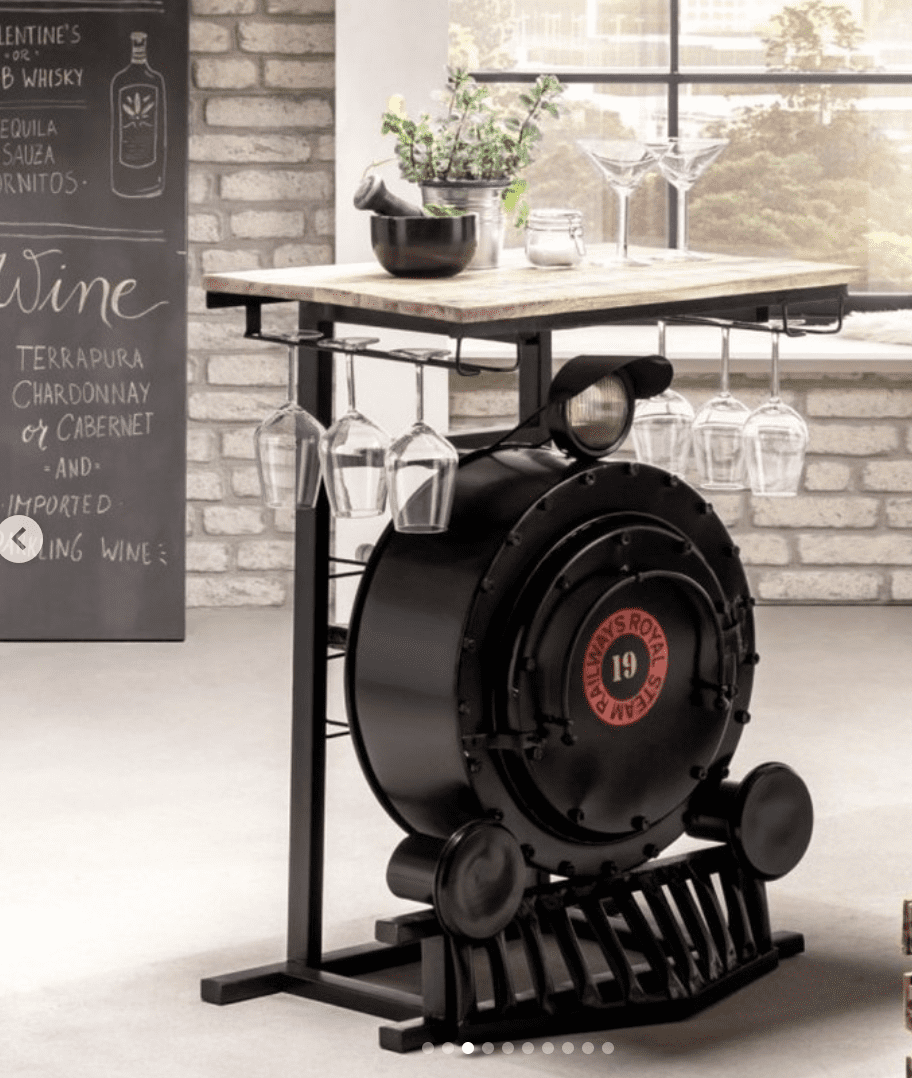

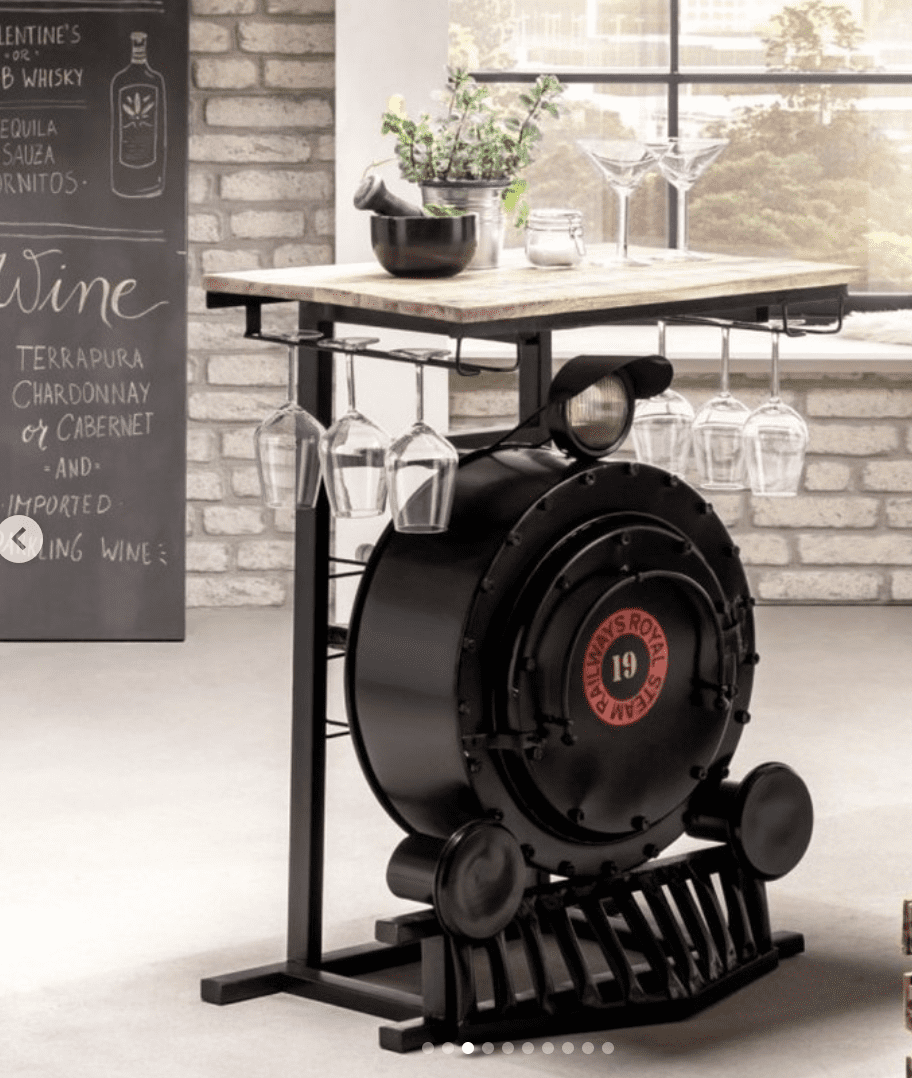

- Deep supplier network: We have long-standing relationships with factories across India, each with varying degrees of skill levels and in many product categories (furniture – décor – textiles – garments, etc., etc., etc.) – so you not only get artisan skill, but also industrial capacity.

- Quality, compliance & sustainability: Audits, testing, ethical sourcing and environmental compliance is built into our entire process, not just something we add as an afterthought.

- Cost control / efficiency: Bringing together demand, so we can negotiate on volumes, optimize production schedules, and have the logistics kind of working themselves out, is all designed for your benefit without compromising on overall value.

- Transparency & communication: Regular updates, samples, reports, photos/videos during production and after inspection. You will know exactly where and, we will know exactly, what is happening with your order.

- Reducing risk: Working through verified suppliers, strong contracts, robust oversight and quality, quality, quality is how we minimize many of the common risks associated with the import/export world (defects, delays, non-compliant materials).

Typical Workflow

Stage | What We Do |

Initial Discussion | Understand your product(s), market specifications, compliance requirements, budget, design preferences. |

Sourcing | Identify potential suppliers, evaluate, send summaries for your selection. |

Sampling / Proto | Make sample(s), allow for feedback & revisions. |

Negotiation & Contract | Lock in pricing, terms, quality specs, lead time. |

Production Oversight | Monitor production, ensure mid‑line checks, fix issues early. |

Final QC & Pre‑shipment Inspection | Check finished goods, ensure packaging & labeling are correct. |

Shipping & Logistics | Arrange transport, consolidation, complete shipping info update |

Post‑shipping Support | Feedback loop, assist with any after‑delivery issues, ensure satisfaction. |

Our Areas of Expertise

- Home décor, lifestyle brands and retailers, furniture, textiles, clothing

- Working with small boutique orders to integrate on‐demand production with larger volume production

- Understanding of export documentation, certifications, and importing requirements for the destination markets

If you are thinking about sourcing from India – a single order or a long‐term supply relationship – we invite you to come to Sri Abhishek Merchandising for assistance as your purchasing agent. Please send through your product brief, sample images, volume estimate, and any compliance, certification, or design requirements and we will send back our sourcing plan, estimated cost, and time for review.