Key Advantages Working with SAM for Furniture

- Material & Construction Expertise

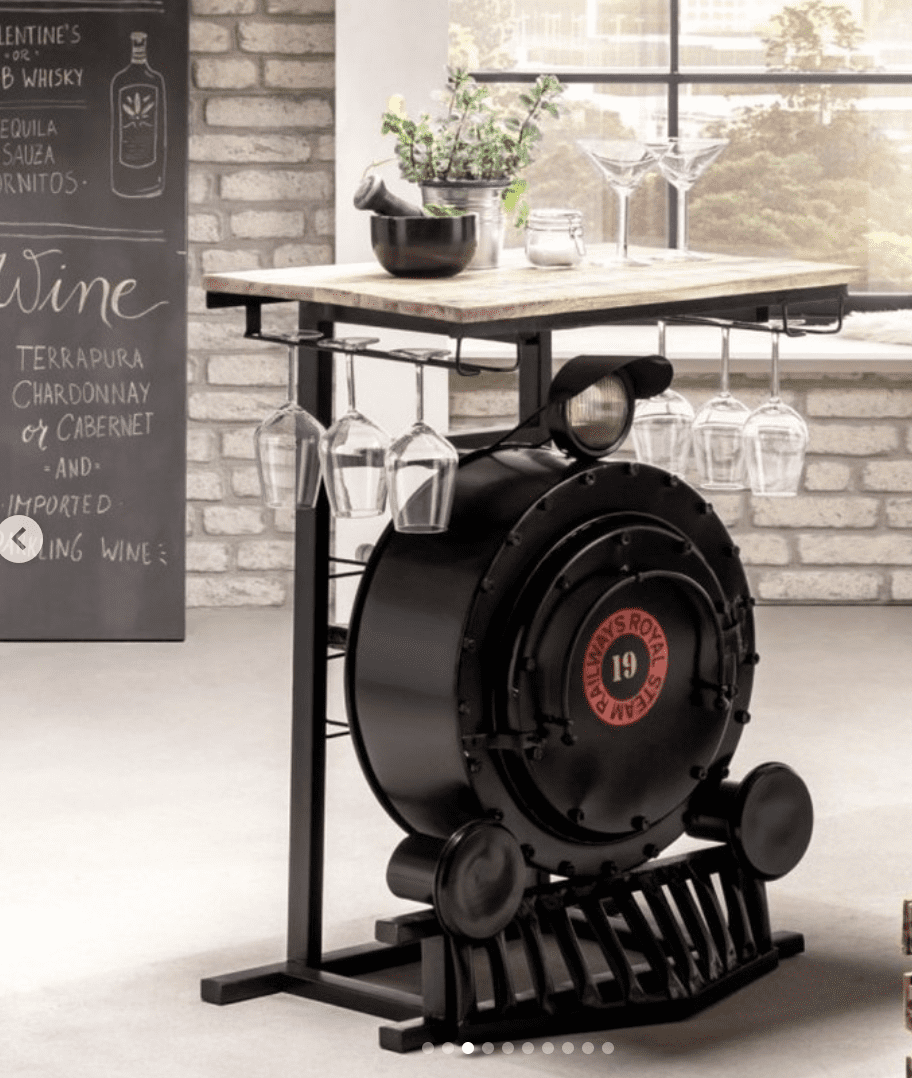

There is a wide selection of wood – teak, mango, sheesham, oak, and engineered wood – as well as metal frames, upholstery fabrics, foam quality, and hardware. We take into account structural integrity and comfort, as well as finish.

You may desire certain styles (modern, rustic, industrial, mid century) and finishes (stained, lacquered, upholstered) for living surfaces. You may also want certain dimensions with combinations of materials. We can control protos and mock ups for your approval prior to us making anything.

- Quality Control & Testing

We check joints, finishes, fittings, upholstery durability, wood moisture, and warping. Indoor/outdoor furniture can require different treatments and coatings (weatherproofing, UV protect, etc.)

- Sustainability & Ethical Production

Certifications and use of timber sourced legally, labor tracking, low VOC finishes, sustainable materials when possible.

- Logistics & Safe Shipping

Furniture can be heavy and bulky, making it easy to break. Proper packaging across each phase of manufacturing and distribution, shipping, customs or in home assembly for customer, flat packing as the last resort to address shipping costs, insuring shipment in advance.

Sourcing Process for SAM furniture

- Schedule & Specification Determining

Establishing the design style (mid-century modern, rustic, contemporary), ensuring the material (hardwood, softwood) sizing, the intended place for use (indoor/outdoor), upholstery and wear-value and then provide budget.

- Vetting supplier/factory

Identifying factory/stores that provide (woodwork, metal work, upholstery) various types of services, to be trustworthy and having gone through an ethical/factory vetting.

- Prototyping/Sample Builds

Establishing a prototypes or sample builds to test for comfort, finish and wear-value the design.

- Monitor production and oversees quality control

Conducting inspection for production both site visit and shop inspection establishing staged inspection checkpoints for joinery, finish and upholstery.

- Packaging & Shipping

Identifying packaging to not damage or break product during shipping providing assembly, while documenting whenever possible.

What You Gain

- Furniture lines that satisfy both design expectations and durability

- Ability to offer custom furniture to clients without needing your own manufacturing setup

- Cost savings via good factory relationships and efficient logistics

Reduced risk — fewer surprises in quality or delivery